Do you need a quotation or advice about our processes and services?

Our technical project manager Caroline Deutschmann, is happy to answer any of your questions.

Contact her directly at +49 (0)2352 9781 0.

JOINING METALS AND MONOFILS

JOINING NON-FERROUS METALS AND MONOFILAMENTS

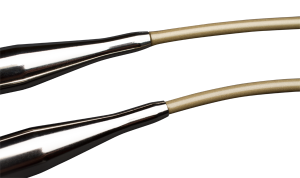

Permanently joining non-ferrous metals and monofilaments

Seltertech can permanently join rounded non-ferrous parts to monofils using a special mounting machine. For monofils, we cover a diameter range of 1 to 3 mm; for non-ferrous metal parts, we cover the diameter range of 2 to 15 mm. The length of the metal pieces may be between 20 and 150 mm; for monofils, we have no restrictions on length. The parts must have an opening or hole that is slightly larger than the monofilament.

ESSENTIALS OF JOINING METALS AND MONOFILS

PROCEDURE

Joining non-ferrous metals and monofilaments is done in a controlled process where a segment tool opens and closes in a clockwork cycle. The metal part is pushed at a defined speed to an adjustable distance in the conical mould. By combining adjustable timing and distance, we achieve a very strong adhesion and a smooth surface area.

Furthermore, the so-called node is formed using a mould. On this end, the monofilament is first heated gently and then enclosed by the mould. By applying pressure to the metal part, the plastic forms into a smooth uniform cone on the attached part.

Compressing plastic and non-ferrous metal

Joining non-ferrous metals and monofilaments is done permanently by compressing the two materials, and carefully avoiding damages to the surface. The print marks and wrinkles from other compression techniques are removed using a specially developed process.

In most cases, it is possible to compress even electroplated or galvanically treated parts such as nickel, chrome-plated or anodized items without causing damages to the surface.

Conical heading for really smooth joinings

After joining monofils and non-ferrous metals, there is still another small section between the two materials, which can be removed using a “node”. By nodes we mean a conical heading of monofilament plastic on the metal part, resulting in a very smooth transition. The “node” does not affect the stability of the connection and is optionally used for items that should have a high-quality look and feel.

TECHNISCHE PARAMETER

TECHNICAL PARAMETERS

Diameter range monofilament: 1 to 3 mm

Length of monofilament: no restriction

Diameter range of non-ferrous metals: 2 to 15 mm

Length of the metal parts: 20 and 150 mm

Metal parts must have an opening or hole that is slightly larger than the monofilament – which we can easily do for you.

ADVANTAGES OF JOINING NON-FERROUS METALS AND MONOFILS

Wherever monofilaments are used to connect, hang or mount an item onto other things, there is a joining between non-ferrous metals and monofils. The metallic pieces may be formed into hooks, loops or end caps and have an internal or external thread or our very own bayonet lock.

Reduced tubes or solid material can be connected directly.

In the areas where it is necessary to join ferrous metals and monofils, compression is another preferred method. The connection is more durable and resistant and can be fitted with a “node”. Plus there are no residues from bonding agents.

- Very smooth transitions between metal and monofilament

- Highly durable joints

- No adhesive application necessary

- Surfaces are not damaged

- Even electroplated parts can be processed

GUSTAV SELTER GmbH & Co. KG

Hauptstraße 2 – 6

58762 Altena

Germany

© COPYRIGHT 2016-2023 GUSTAV SELTER GMBH & CO. KG